Electronic Ballast Design

Introduction To Electronic Ballast Design

Fluorescent Lamp was introduced commercially in the 1940s and was a success in small scale lighting replacing the use of tungsten incandescent bulb. It continued to be used in the 21st century and has since evolved into many variation of outlook, applications and control.

Two main functions of a fluorescent lamp ballast are providing a starting kick and to limit the current to its operating value for the tube that is being used. There are basically 2 types of ballasts namely magnetic ballast and electronic ballast design. The magnetic ballast uses a core and coil assembly transformer that provides a minimum functions of starting and operating the lamp.

Hence it is not as efficient as the electronic ballast. Electronic ballast operates at high frequencies from 20kHz to 45kHz and uses electronics circuitry to optimize the operation of the lamp.

Electronic ballast design is becoming more common due to its superior performance. It outputs 10%-15% more light output, does not have the 50/60 cycles irritating hum, high frequency switching that does not have visible flicker to the human eyes, cooler and more reliable. Though its initial cost is higher than the magnetic ballast, its payback will come in the long run. Operating the ballast at higher frequency means that the design can be smaller and made compact. It utilizes the switching mode power supply technology in its implementation.

Magnetic and electronic ballasts can be categorized into 3 categories - instant start, rapid start and programmed start.

Instant start ballasts require an instant-start certified lamp and ignite a lamp in about 80 milliseconds or less using a high frequency electronic circuit. It starts the lamp without heating the cathodes by using a high voltage at around 600V.

It is the most efficient energy type when used in installations where the lamps are not turned on and off regularly.

Rapid start ballasts precisely heat the cathodes and then ignite the lamp with a lower charge. In this way, it helps to prolong the life of the lamp but it uses more energy as the cathodes are heated up continuously during the operation of the lamp.

Programmed Start is an upgrade version of rapid start. It allows the cathodes to be preheated before applying the voltage to the lamps to strike an arc. This type gives the best life to the lamps and is used in applications where frequent ON/OFF of lights are required.

Electronic ballast must be designed, installed and operate in compliance with the CSA, UL and NEC requirements. As the installation and testing come in contact with hazardous voltage, only qualified personnel should perform the installation. It should be done with the power to the lamp turned OFF.

Compact Fluorescent Lamp (CFL) Electronic Ballast Design

One of the advancement made in the field of electronic ballast control is the invention of compact fluorescent lamp or CFL in short. It is also known as energy saving light bulb and is usually screws into the standard light bulb socket or plugs. Common screw type size used is E27. Compared to incandescent bulb, it have a longer rated life and uses less electricity though its initial cost is higher.

Two main parts to a CFL are the gas filled bulb and the electronic ballast. Electrical energy flows though the gas causing it to give off ultraviolet light(UV light) that excites a white phosphor coating on the inside of the tube. This coating emits visible light.

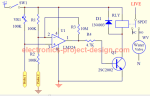

The application note from International Rectifier provides the design of a 13W CFL compact using an IR53H420 Integrated Half-Bridge device. It is able to drive a 13W lamp from 110 or 220 VAC input, 34kHz frequency of operation and Softstart with cathode preheating.

Back To Electronic Ballast Design Home Page

New! Comments

Have your say about what you just read! Leave us a comment in the box below.